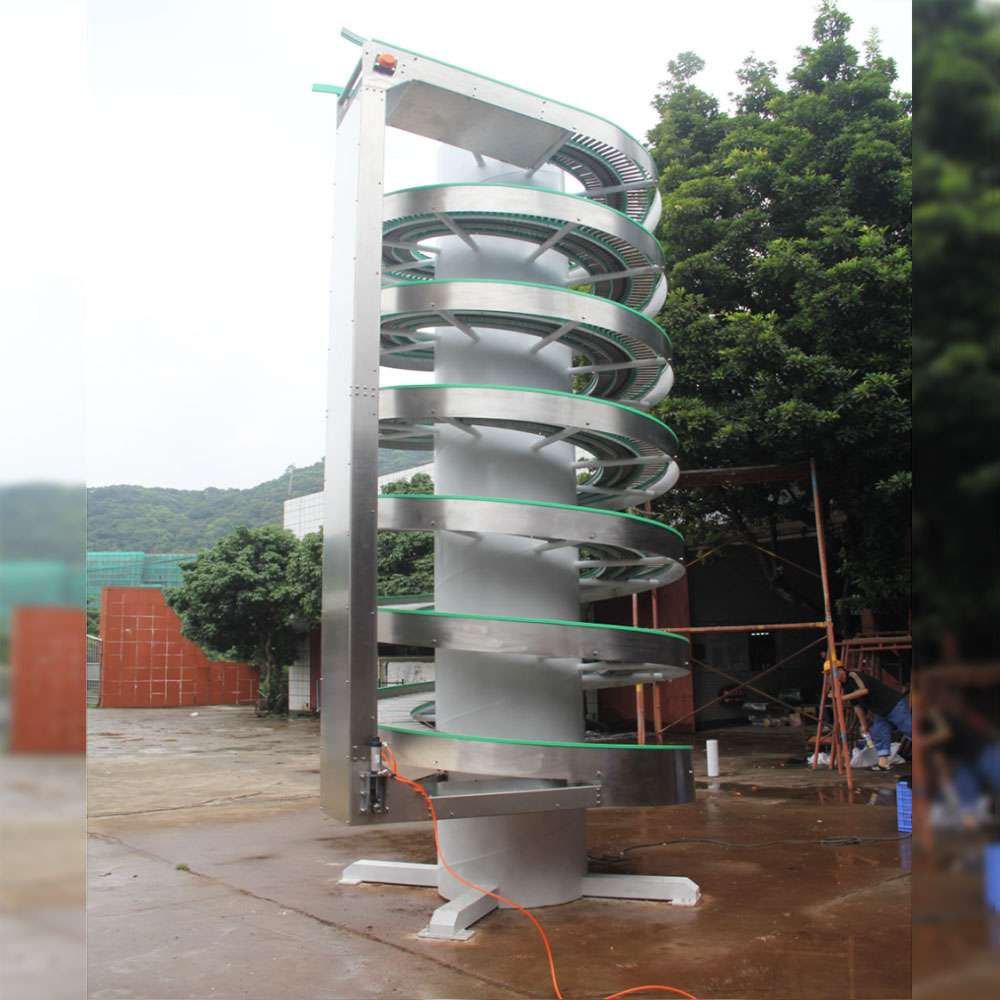

Fully Automatic Vertical Spiral Conveyor

Pillar Rotary Tower

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

A vertical spiral conveyor is a device that transports materials vertically in a spiral path. Using a spiral conveyor belt or track, it lifts materials from a low location to a higher one, or transports them from a high location to a lower one. This method of conveying enables efficient vertical material transport within a limited space, making it particularly suitable for use in space-constrained environments.

Fully Automatic Vertical Spiral Conveyor Specifications

| Product Name | Fully Automatic Vertical Spiral Conveyor |

| Model | KC-ZSX-01 |

| Voltage | 380V3N |

| Power | 1.5kW |

| Width | 1000-3000 |

| Height | 1000-10000 |

| Conveyor Material | POM |

| OEM/ODM | Accept |

| Compay Nature | China Manufacturers Suppliers Factory |

Fully Automatic Vertical Spiral Conveyor Advantage

1. Food-Grade Materials:

The Fully Automatic Vertical Spiral Conveyor uses food-grade POM conveyor belts, which are high-strength, wear-resistant, and corrosion-resistant. POM meets food hygiene standards, ensuring product contamination during conveyance. It is also easy to clean, effectively preventing bacterial growth and ensuring food safety.

2. Efficient Space Utilization:

The Vertical Spiral Conveyor's compact design enables efficient material conveyance within a very small space. Its height can be adjusted from 1,000 to 10,000 mm, and its width can range from 1,000 to 3,000 mm. Its spiral rise and fall mechanism significantly reduces floor space, making it particularly suitable for space-constrained production environments such as small bakeries or food processing plants.

3. Stable Transmission:

The Fully Automatic Vertical Spiral Conveyor utilizes a stable transmission system equipped with a 1.5kW motor and a 380V three-phase power supply, ensuring smooth and reliable conveying. Its composite plastic-steel conveyor belt maintains stability at high speeds, preventing material from shaking or dropping during conveying, thereby ensuring production efficiency and product quality.

4. Intelligent Control:

The Vertical Spiral Conveyor features a fully automatic intelligent control system with an intuitive touchscreen interface. Operators can easily set parameters such as conveying speed and direction through the screen, achieving efficient and energy-saving automated production. The control system complies with industry standards, offering high stability and low failure rates, making it suitable for both batch and continuous production.

5. Customizable Design:

The Vertical Spiral Conveyor can be customized to meet specific customer needs. Customers simply provide product dimensions and conveying requirements, and our engineers will design a spiral tower to meet these requirements, ensuring stability and efficiency. Customized designs can meet diverse production needs and enhance the equipment's adaptability.

6. Low Maintenance Cost:

The Fully Automatic Vertical Spiral Conveyor is designed for ease of maintenance. Durable materials are used in the conveyor belt and drive system, reducing the need for routine maintenance. At the same time, the equipment has a simple structure and is easy to disassemble and clean, which reduces maintenance costs and downtime and increases the service life and production efficiency of the equipment.

1. Baking Industry:

Fully Automatic Vertical Spiral Conveyors are widely used in the baking industry for the production of baked goods such as mooncakes, hamburgers, and cakes. They can transport ingredients such as dough and fillings from low-lying areas to high-level processing equipment, or from high-level cooling racks to packaging equipment. Their stable conveying performance ensures the integrity of food during production, preventing squeezing or deformation.

2. Food Processing Industry:

Vertical Spiral Conveyors are suitable for a variety of scenarios in the food processing industry, such as meat processing and fruit and vegetable processing. They can transport raw materials from cold storage to processing workshops, or move finished products from processing equipment to packaging lines. Their food-grade materials and easy-to-clean design meet food hygiene standards, ensuring hygienic and safe processing.

3. Logistics and Warehousing:

Vertical Spiral Conveyors are used in logistics and warehousing for vertical transport of goods. They can transport goods from ground-level shelves to high-level racks, or from high-level racks to ground-level transport equipment. Their compact design and efficient conveying capacity significantly improve logistics and warehousing efficiency, saving space and time.

4. Industrial Production:

Vertical Spiral Conveyors are used in industrial production to transport various parts and raw materials. They can transport materials from one production process to another, or from warehouses to production lines. Their stability and durability enable them to withstand the intensive demands of industrial production and improve production efficiency.

5. Beverage Industry:

Vertical Spiral Conveyors are used in the beverage industry to transport beverage bottles, cans, and other packaging materials. They can transport empty bottles from washing equipment to filling equipment, or finished beverages from filling equipment to packaging equipment. Their stable conveying performance and food-grade materials ensure hygienic and efficient beverage production.

6. Pharmaceutical Industry:

Fully Automatic Vertical Spiral Conveyors are used in the pharmaceutical industry to transport materials during the pharmaceutical packaging and production processes. They can transport tablets, capsules, and other materials from production lines to packaging equipment, or from warehouses to production workshops. Their hygienic design and stable conveying performance ensure the quality and safety of pharmaceutical production.

Fully Automatic Vertical Spiral Conveyor FAQ

Q: What are the main features of the multi-column spiral tower?

A: The multi-column spiral tower features an aesthetically pleasing and sturdy design, with smooth conveyance and low maintenance costs. Additionally, we can customize the size according to customer requirements, making it ideal for batch and continuous production.

Q: What industries or applications is this spiral tower suitable for?

A: The multi-column spiral tower is widely used in the food industries, particularly suitable for scenarios requiring vertical or inclined material conveyance.

Q: What is the process for customizing the size?

A: Customers only need to provide specific size requirements and conveyance needs, and our engineers will design a spiral tower that meets your requirements while ensuring stability and efficiency.

Q: Why is the maintenance cost of the spiral tower low?

A: Our spiral tower features a simple design with easily removable and replaceable parts, and uses wear-resistant and corrosion-resistant materials, reducing the cost of daily maintenance and repairs.

Q: How do you ensure the smooth conveyance of the spiral tower?

A: The multi-column spiral tower adopts advanced transmission systems and structural designs to ensure smooth and bump-free conveyance of materials, protecting them from damage during transportation.

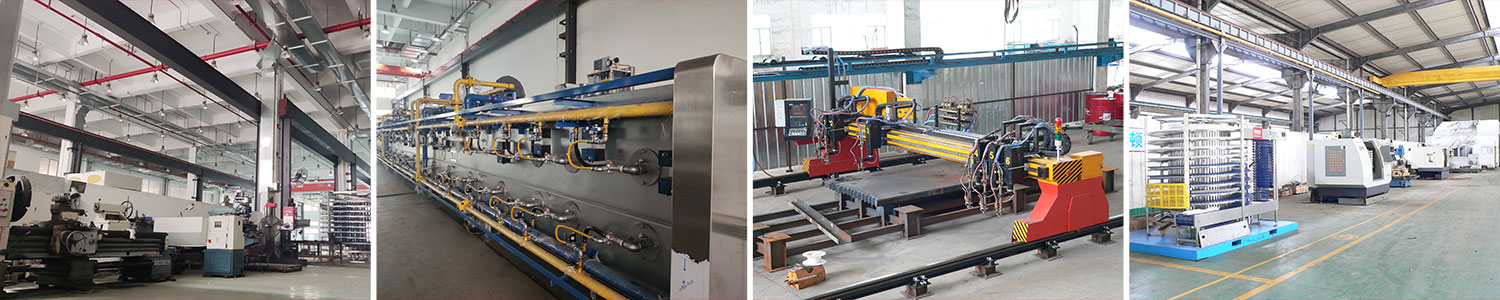

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

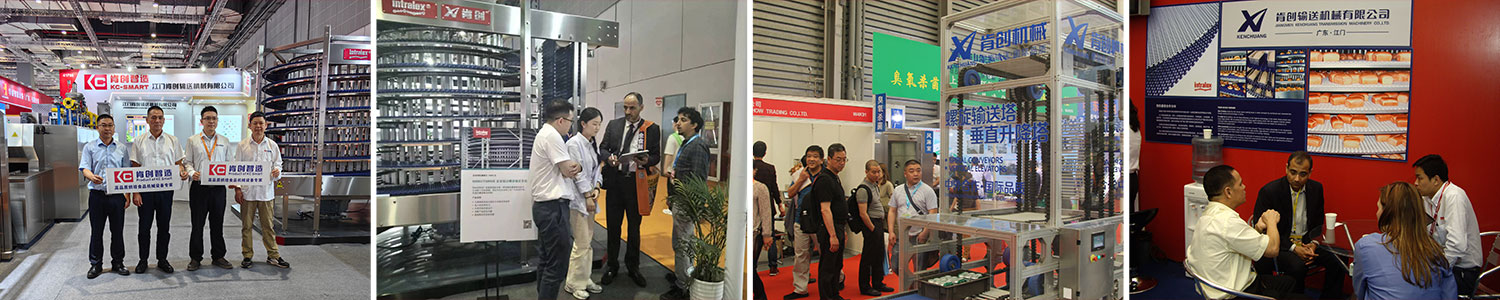

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.